Visiting Haibike HQ

Issue 76 / Mon 10th Jul, 2023

Razzing around Schweinfurt singletracks, visiting an impressive warehouse and meeting the people that make Haibike tick.

Beep beep beep goes the alarm clock. It’s 5am on a Wednesday and it’s time to jump in the car to the airport. A 9:15 flight sounds like a reasonable time to fly, but factor in the security ports, passport control, a 1,5h drive to the airport and suddenly you are standing next to your bed before sunrise.

Don’t get me wrong, I am an early riser in general and when there is a bike trip involved I’ll hop out of bed with ease. Especially after a long time of ‘online product releases’ I am more than stoked to go to new places and meet some new people. And of course ride some cool bikes!

History

Founded in 1995, Haibike started out as part of Winora, a company that has been making bicycles in the German town of Schweinfurt since 1921. Integrated into the Accel group since 2001, the main focus of Haibike has always been innovation and sports oriented bikes. In the 2012 Olympics the German Sabine Spitz managed a silver medal on her Haibike and it was around this time that the first E-bikes started emerging onto the market.

A firm believer in E bikes from the start, Haibike was constantly on the forefront pioneering full suspension models, e-road bikes and a technique called ‘gravity casting which allowed them to produce highly complicated frame shapes with incredibly tight tolerances. This made mounting e-bike motors and batteries possible at a large scale production.

In 2018 they launched their Xduro bike. Until this moment e-bikes were mainly aimed at commuters and leisure riders but the 180mm travel beast of a machine brought the technology to the attention of the more extreme mountain bikers, tapping into a whole new market.

If you look closely at their catalogue today, you will see there is not a single ‘acoustic’ bike in their line up. They are 100% committed to e-bikes and are still pushing the envelope today with new concepts developed together with their ambassadors, dealers and customers.

Logistics

The flight into Frankfurt is a straightforward job, and after a short wait for some other guests we make our way over to Schweinfurt where we meet up with Gareth from Haibike UK and Matthias the Brand Manager. As we’re a little on the late side we jump straight into the warehouse tour.

Besides hosting the brand new Haibike showroom and training facility, this location also holds stock for sister company Wiener Bike Parts, one of Europe’s largest wholesalers. With over 25.000 different bike parts in stock, the operation is gigantic.

As we move through the various halls and storage areas, we’re explained that this facility has been growing for decades in line with the business. As the business grew larger and larger, the neighbouring buildings, offices and warehouses were bought and converted to house Haibike and Wiener Bike Parts.

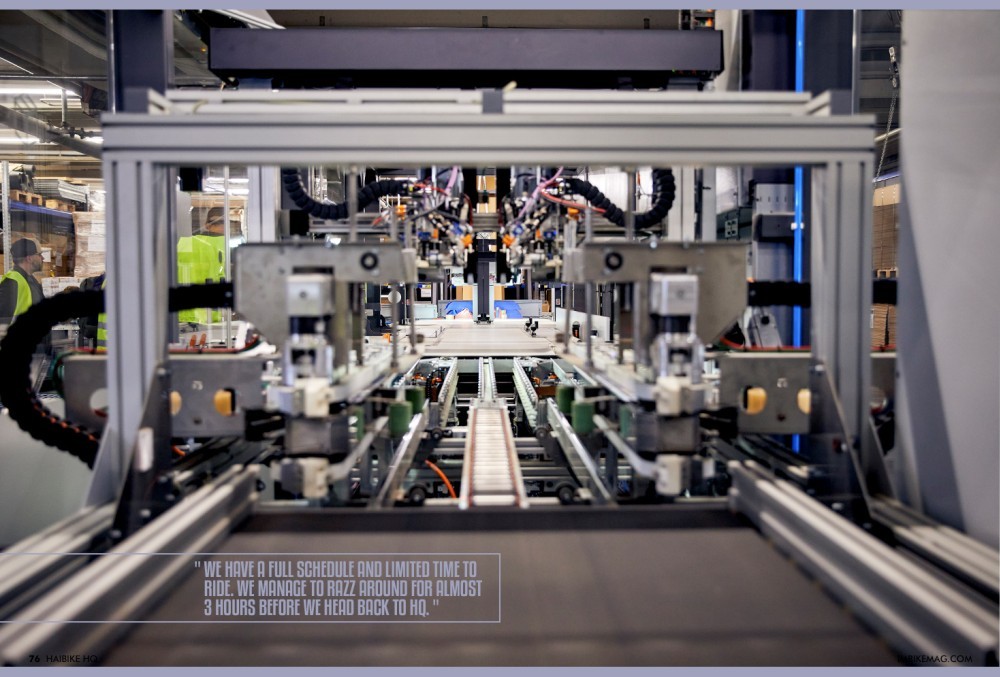

The result is an impressive maze full of bike parts. As we wind through the buildings I notice that none of the items are in any logical order. After asking about it, the explanation seems logical. Items are stored in the most space efficient way possible, all determined by computer software. Orders are processed and packed within 24 hours and shipped Europe wide.

The coolest machine in the warehouse is definitely the ‘automated boxing machine’. Just scan the order, put the items onto the machine and it will measure, cut, fold and label the package in seconds. Not only is this lightning fast, but it also reduces cardboard use by almost 50%.

Last stop on the tour is the Haibike Workshop. The bike mechanics dream! These days it is mainly used for building photo samples, prototypes and the odd pre production bike as the main assembly of Haibikes are done in a different location. Still, they kept this part of the workshop as they wanted to be able to stay flexible and have a proper facility on site.

Day 2

With the delays of day 1 our program for day 2 got a lot busier. After breakfast we head straight to the brand new Haibike training facility, a 3000m2 showroom with a presentation area to show off bikes, kit and technology. It’s always nice to speak to the people behind the brand and get some more information from the horse’s mouth.

A dozen slideshows later, it’s time for the best bit of the trip. Riding bikes! We make our way to the demo area and get the bikes dialled in and set up. I have the latest version of Haibike’s lightweight E-MTB, the Lyke, waiting for me (see the full review in the Tried and Tested section of IMB 76). Tricked out with XTR brakes, carbon wheels and Srams brand new XX Eagle groupset this is a dream machine!

As we head out of the industrial area towards the trails, I get familiar with the fresh ride. This is the first time I am able to use the Fazua Ride60 system and the first thing I notice is that it is really silent. You can barely hear the motor purring and with 60Nm there is plenty of torque on the steeps.

Riding in the area is surprisingly fun. No it’s not a proper bike park or trail centre, but in the woods right next to Haibike HQ there are tons of trails that link together like a big singletrack maze. Some fast, some more technical and all a blast on the Lyke. We even come across a jumpline which we hit a couple times in a row, because that's what e-bikes are good at right?

Weighing in at just over 18kg the Lyke handles like a normal bike, but it still allows you to blast up the hills like with a ‘proper’ e-mtb. Perfect for a day like this where we have a full schedule and limited time to ride. We manage to razz around for almost 3 hours before we head back to HQ. Just as I turn onto the Haibike HQ compound my battery dies, after about 900m of climbing and about 40 km distance. As we were blasting around in Turbo mode for 90% of the time these numbers are very impressive!

Warp Speed

After a power shower and hearty lunch we take a tour through their 2024 embargoed showroom. Sadly I can’t share any of the news I saw up there at this moment, but I can say the future is bright and Haibike has got some amazing new products lined up.

With my flight leaving early evening, it’s time to hop into the van for a high speed transfer to Frankfurt Airport. As most of you know at some points on the German motorways, there is no speed limit. It sure makes an otherwise mundane commute feel like a Disney attraction when you are swooshing on the Autobahn at 220 km/h! Didn’t even know these vans could go this fast.

Needless to say we arrived in time for our flight and before I knew it I woke up in my own bed again. A great experience and impressive operation they have, I can’t wait to show some of the 2024 highlights with you in future issues.

By IMB