New Flat & Riser Handlebars From Beast Components

Fri 11th Jun, 2021 @ 12:30 pm

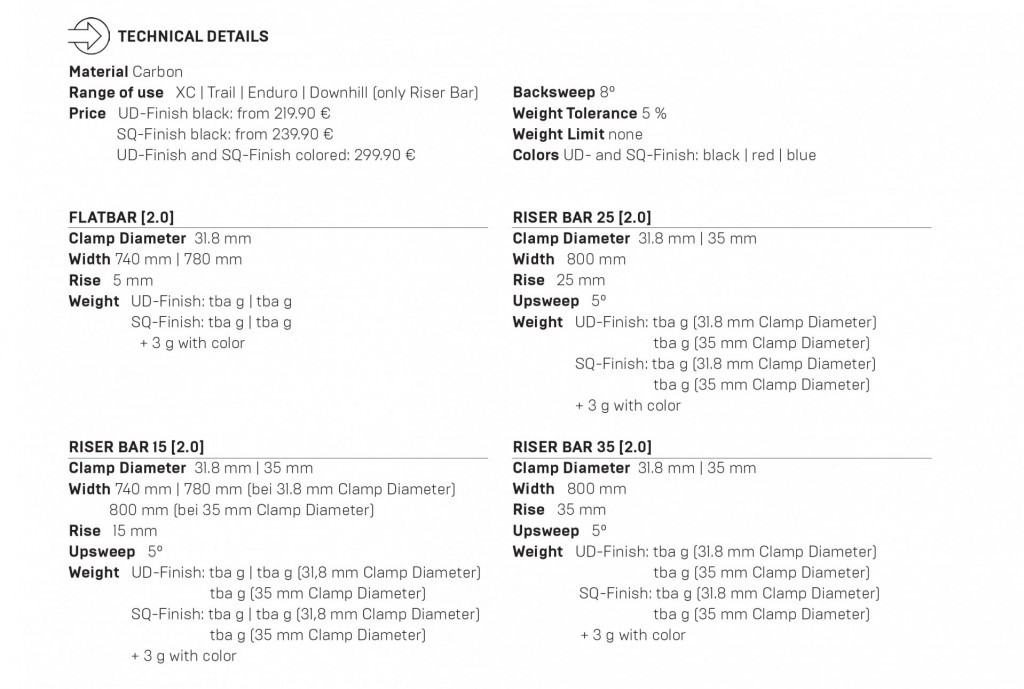

And for once, these aren’t lighter than their predecessors, in fact these are slightly heavier than before but are claimed to be much more durable, who wouldn’t want a more durable carbon handlebar?! Full press release from Beast Components below:

Beast Components Launch New FLAT BAR [2.0] & RISER BAR [2.0]

MTB handlebars made of carbon are very controversial. We at Beast Components understand the controversy and are eager to join the discussion because the handlebar is and remains one of the most safety-relevant components of the bike and its worth taking a closer look.

With pleasure we would like to inform you that our proven MTB bars have received an upgrade, so you have the free choice of brakes without having to worry about unfavorable clamping. A tad heavier than before, but a lot more stable, this carbon handlebar withstands the toughest industry test in the world.

Why We Had To Make Adjustments

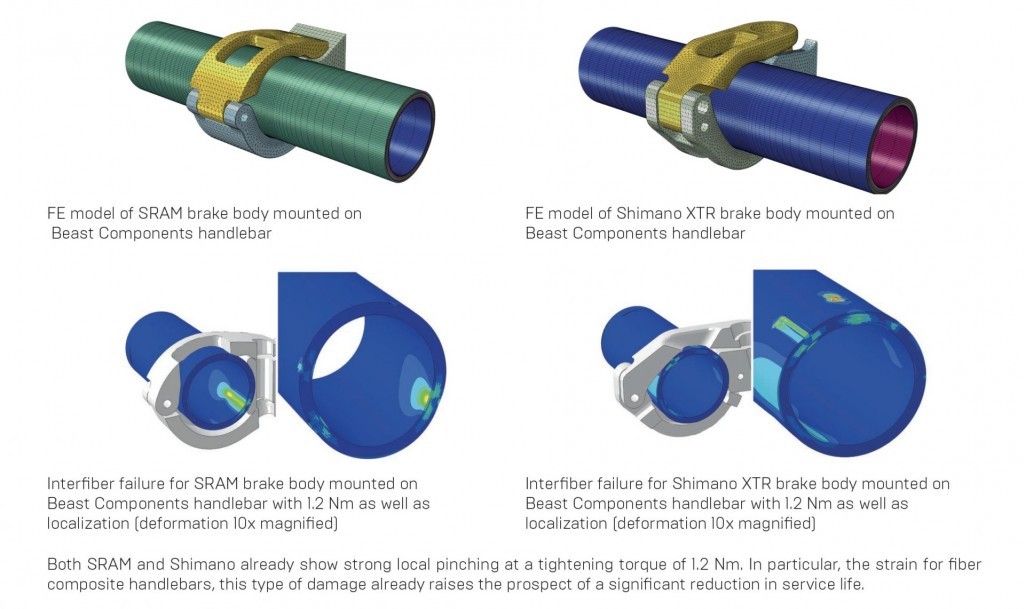

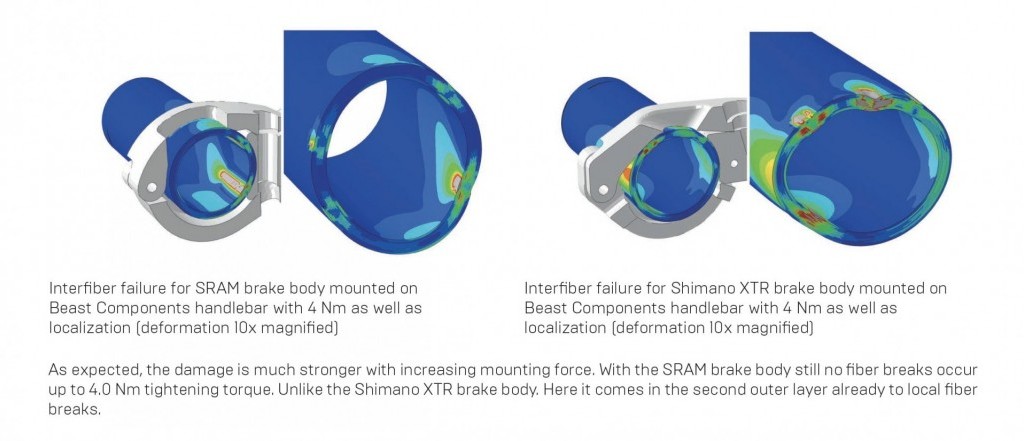

Some new brakes and clamps on the market (including those from Shimano and SRAM) have a very unfavorable clamp design for carbon and lightweight handlebars. The clamps are not round, and the contact surface is minimal. Loads are thus no longer distributed evenly over the clamping area of the handlebars instead applied on point. This squeezing principle of the new brake clamps is pure poison for any carbon structure. You don‘t have to be an engineer to understand that loads acting like this on the handlebars cannot be distributed in an appropriate way.

Thanks to our close cooperation with Realize Engineering, a development service provider specialized in high-tech lightweight construction, it was no problem to take a closer look at the most common brakes on the market using finite element analysis. The results were alarming. Below you will find a few excerpts from the scientific study:

That’s New

To achieve even greater safety and fatigue strength, we have once again looked at the structure of our handlebars in the clamping area of the brake levers. In addition to the new and even more sophisticated and load-oriented layer structure and a very elaborate fiber arrangement, we now use a special mesh made of polyester for our Riser and Flat Bars. This mesh has the following positive properties for us: It has a high strength and retardation and at the same time a low sliding friction and great durability against wear due to sliding action.

We used it exclusively in the clamping area of the brakes. Thus, point loads are absorbed much better and distributed evenly over the handlebars. Impressions of the clamps are reduced to a minimum and the carbon layers underneath are protected. It is a safety buffer to the pressure-sensitive carbon surface and allows the free selection of the desired brake and the use of a higher tightening torque. For example, brakes with an unfavorable clamping design can now be tightened with a maximum of 3 Nm, as instead with a maximum of 1,5 Nm as was previously the case. Brakes with advantageous clamping design even up to 6 Nm. Drag marks due to frequent loosening and reattachment of the brake as well as frequent twisting, e.g. as a result of a fall, are prevented.

Safety Comes First

The polyester prepreg mesh we use blends discreetly into the appearance of the handlebars, yet breaks through the fiber structure. If fittings and grips are installed, the new clamping area is hardly noticeable. We accepted the visual change and the extra weight of about 20 g compared to the old models, because it provides our and your customers with more safety. And that‘s what it should come down to.

To achieve this new level of safety we have established a more extensive test procedure. Thereby, the new Riser Bar 2.0 and Flar Bar 2.0 models must pass an extended and above all more realistic Multi-Load test than before. It includes, for example, twisting the brake clamps five times with a tightening torque of 1.5 Nm and tightening and loosening the brake clamps ten times with a tightening torque of 4Nm before the actual test starts.

For more info, be sure to head on over to beast-components.de