Loic Bruni & Danny MacAskill’s Custom MAGURA Levers

Mon 25th Jun, 2018 @ 3:30 am

No one’s hands are the same – so why should all brakes have the same lever? DH World Champion Loic Bruni and MAGURA went in search of the perfect lever ergonomics – and failed. Instead gaining the knowledge that: ergonomics is a completely individual matter. With the product program #customizeyourbrake MAGURA offers end customers the possibility to adapt their lever ergonomics to their own preference.

The work with Athletes has been of immense value to MAGURA. Professional riders like Danny MacAskill and Loic Bruni give valuable insights into the needs of accomplished athletes. The resulting ideas often lead to production-ready products. One good example for this is the HC3 1-finger brake lever for the MAGURA MT7: it was developed together with Danny MacAskill and is now one of the most sought-after retrofit parts for ambitious bikers.

“Loic’s requirements were quite extreme. He wanted the bite point far away from the handlebars but with an extreme leverage ratio for full on/off braking power. All or nothing.“

– Reiner Künstle, development engineer at MAGURA

Tailor-made for the world champion

From the start of 2018 MAGURA has officially sponsored the Specialized XC and Gravity Team with our brakes. After the first test camp, it soon became clear that, in particular, world champion Loic Bruni had his own, very precise ideasabout braking performance – especially about the ergonomics and the operation of the brake. In a first sketch Loic drew the shape of his desired lever on paper.

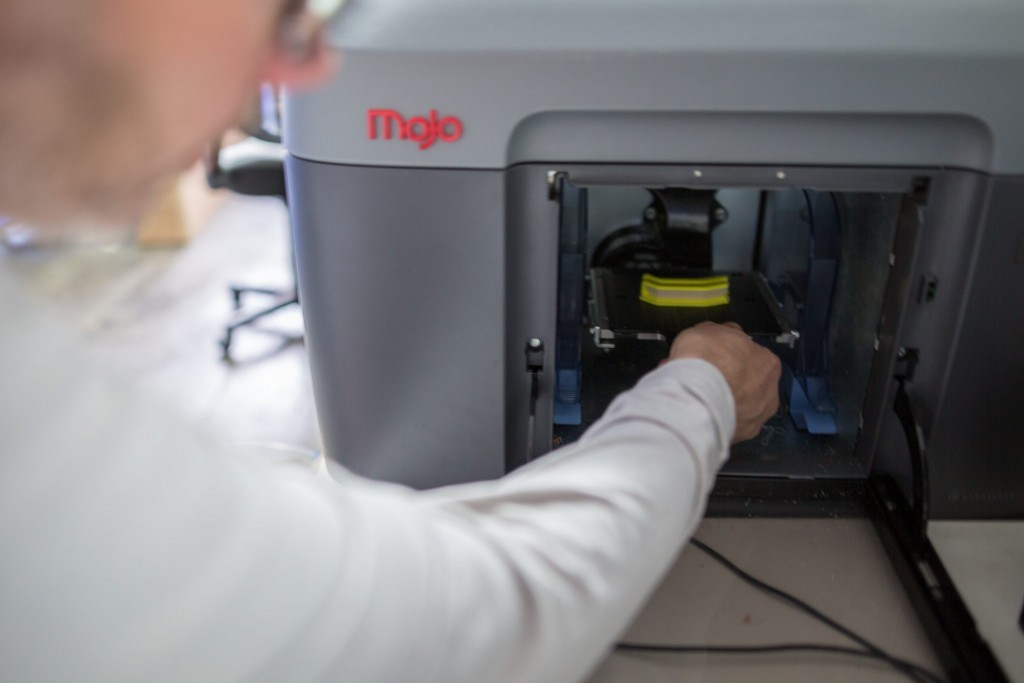

To better understand his needs and to enable practical testing MAGURA’s development department developed a prototype as a basis for testing. The “Loic-O-Mat”, as it was called, with a wink, is a combination of a permanently-mounted, aluminium base lever and 13 variations of 3D-printed lever shapes that could be installed and replaced quickly and easily. Loic tried out all the different shapes and lever ratios under real-life conditions and ultimately found his perfect lever form. On this basis MAGURA produced a perfectly tuned lever for Loic which was used at the world cup race in Fort William for the first time.

“The short shape of the lever is more flat and straight. At the bite point, the lever is almost parallel to the handlebars, so his finger won’t slip in this position. Loic can move his finger on the wide grip area and take the pressure off it”, says Reiner Künstle, development engineer at MAGURA.

The final prototype of Loics lever is made of 3D printed titanium.

Through the use of rapid prototyping the development team were able to realise very short production times without compromising the strength or weight of the lever.

Danny MacAskill: Perfect Ergonomics for Maximum Precision

The collaboration with Danny MacAskill produced a completely different lever than Loic Bruni’s choice. Danny prefers a short brake lever with a minimum reach to keep a firm grip on the handlebars when he jumps from house roofs and during hard landings.

“Danny wanted a completely different feel in his brakes than Loic. As well as having the lever close, he wanted a clear position for his finger. To achieve this, the HC3 lever has almost a recessed grip with a high tip. It’s nothing like Loic’s flat lever”

– Reiner Künstle

The edges of his lever are rounded and flat to prevent his fingers from being cut. Thanks to the adjustable transmission ratio of this lever he can change the brake power and modulation. This enables him to stay in control, even in wet conditions. There’s no room for compromise if you have to land on an area the size of a 1 Euro coin from a height of 2 metres.

“The requirements of our athletes differ enormously. We offer them and our customers different lever options to provide the best individual ergonomics and control“, states Heiko Böhle, Head of Product Management at MAGURA.

What if I’m not a pro?

#customizeyourbrake

In order to utilise the knowledge obtained by the close cooperation with pro-athletes, MAGURA already can offer a wide range of levers for model year 2019: four levers made of aluminium and carbon and with different ergonomics are available as retrofit parts for end customers. The new range includes Danny MacAskill’s HC3 lever and a new 1-finger lever produced using the carbon-textile embroidery process. The Loic Bruni lever prototype is currently in its intensive trial phase, during which other athletes test it and give us their optimisation suggestions.